AeroVironment

Aeromechanical Engineer III• July 2021 - Present

I currently work as the team lead for the Jump-20 maritime aircraft project team and am responsible for the design, prototyping, and testing of a new

aircraft variant that is capable of operating in maritime environments, including shipboard launches and landings. I lead daily scrums for a team of five

engineers and two engineering development technicians, plan and execute flight testing events, and develop/manage project timelines and budgets.

I was previously the project team lead for a development effort that increased the Jump-20s cold weather tolerance. I led a team of 2 engineers and two technicians

to design and prototype a ‘bolt-on’ cold weather kit for existing aircraft. We were successful in lowering the aircraft temperature limitations from +32f to

-40f with a 1% increase in weight and less than a 5% decrease in endurance. In addition, I handled multiple mishap investigations, applying root cause analysis techniques

to prevent future incidents and optimize safety protocols.

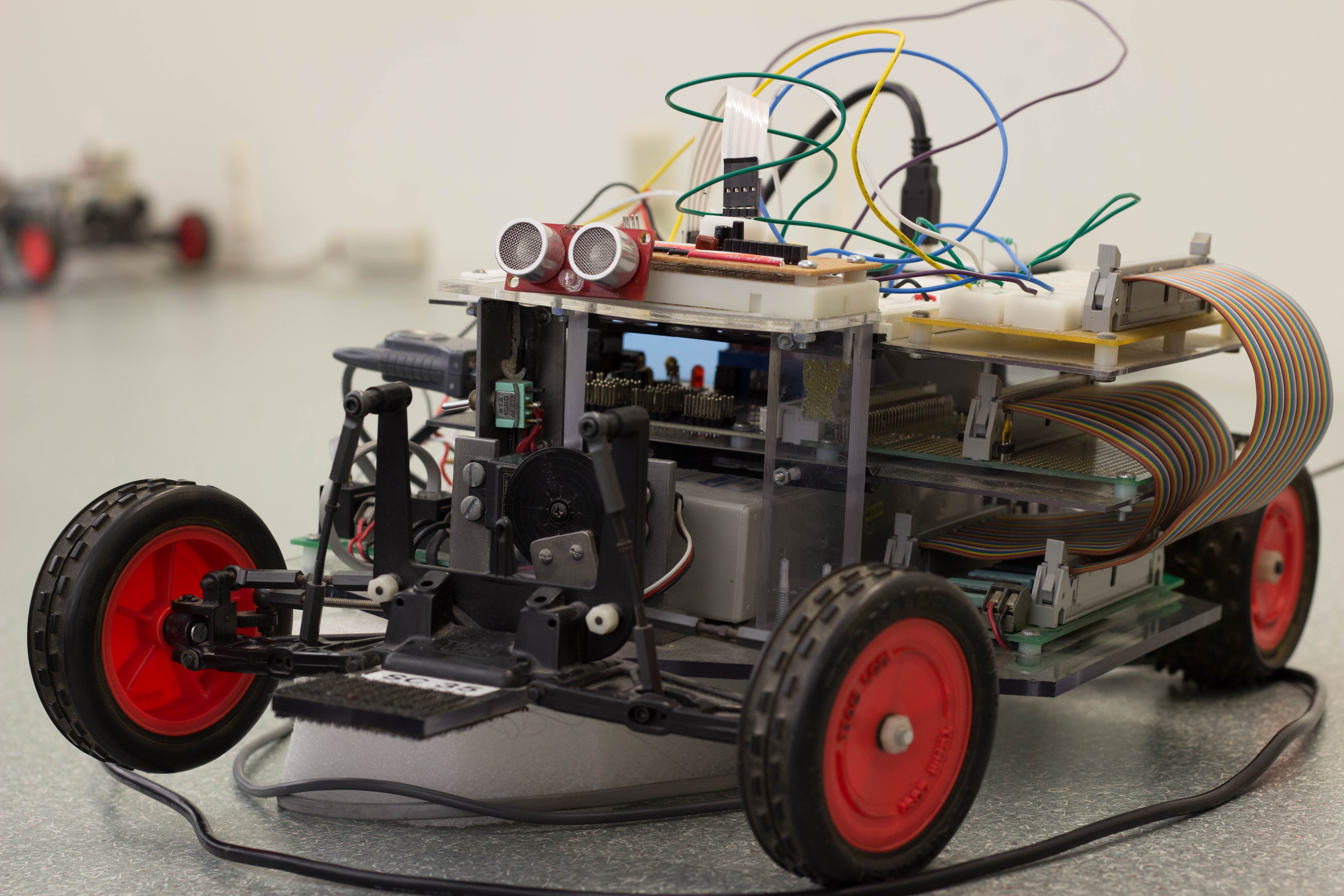

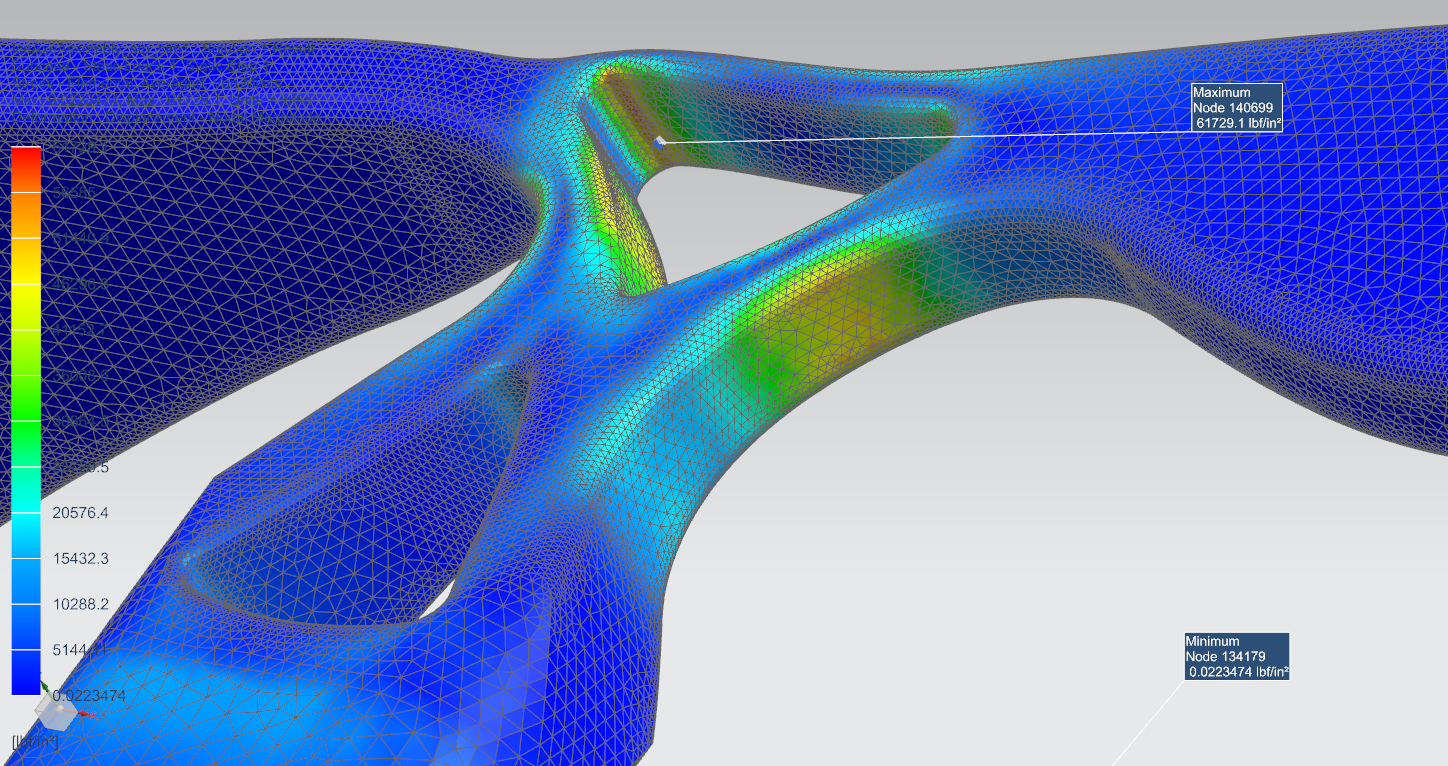

My previous role at AeroVironment was as a Mechanical Engineer II working in the special projects division where we completed clean-sheet design projects from start to finish, including design,

analysis, testing, and manufacture. This was a hands-on process, and where I gained valuable fabrication knowledge that aids in my ability to rapidly manufacture prototypes.

AEROSONIC

Aeronautical/Mechanical Intern• May 2019 - August 2019

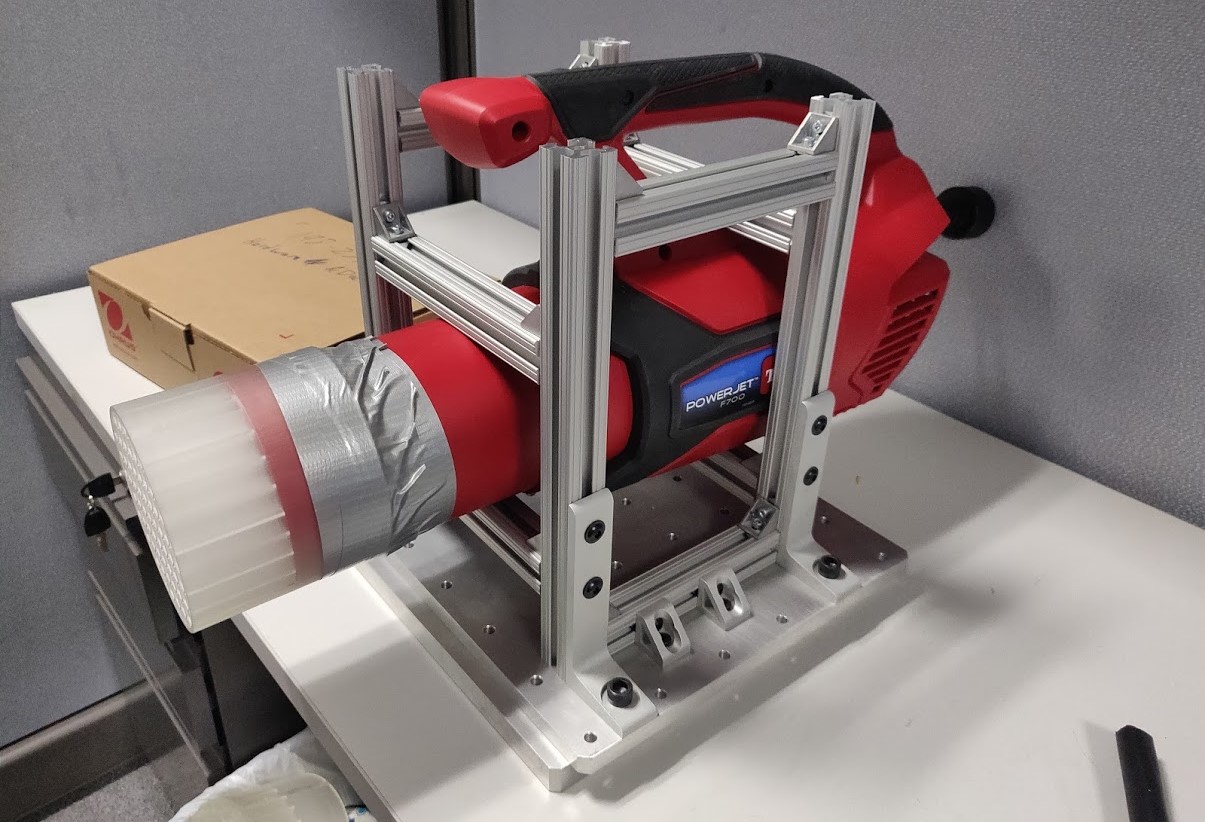

I worked as an Engineering intern for AEROSONIC, a Florida-based engineering firm which specializes in aircraft instrumentation. I specifically designed,

built, and analyzed engineering test fixtures for experimental Pitot-static and angle of attack sensors. Additionally, I worked in Solidworks to create

engineering models and drawings, and worked closely with a manufacturing team to fabricate these test fixtures.

Architecture Shop Fabrication Assistant

Rensselaer Architecture Shop Assistant• May 2018 - March 2020

I worked as a Fabrication Assistant in the Rensselaer Architecture shop. I fabricated various models and experiments designed by professors.

I also worked as a shop supervisor, overseeing various student projects. I also worked in shop upkeep, installing pressurized air lines and various

laser cutters, including designing air filtration and exhaust systems. Additionally, I designed an automation system to allow personnel who have been

trained in a machine to activate said machine using their school ID.

National Institute of Standards and Technology (NIST)

Summer Undergraduate Research Fellow• May 2017 - August 2017

At NIST, I worked in the Engineering Laboratory as a part of their Flammability Reduction group. Using

Thermogravimetric Analysis, I performed high precision laboratory experiments on different samples of

vegetation. I then wrote several scripts in python to determine the kinetic parameters of several

different species of vegetation, in order to use NISTs fire dynamics simulator to more accurately

predict wildfire behavior.